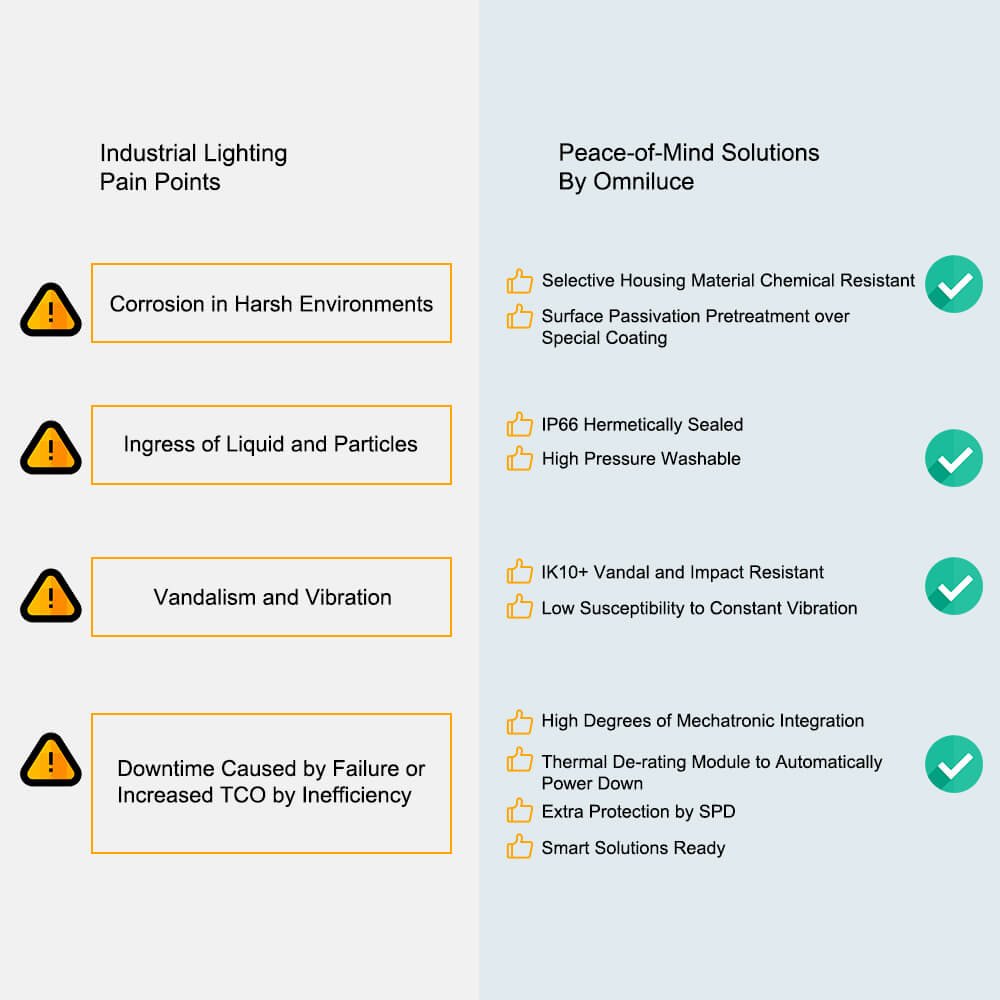

Lighting is only a small part of any industrial operation but carries a colossal impact because most operations rely on lighting for half the time.

Thus the peace-of-mind total solutions consolidated to deliver lighting fixtures built to last and keep operational for years ahead without maintenance are of paramount importance.

With extensive research into the industrial and outdoor lighting, we identified all the critical factors and pinpointed the application-specific solutions to address the issues.

Marine Grade Material Immune To Corrosion

One of the keys to the corrosion resistance of our light fixtures lies in the material options we use to produce heatsinks. Fully aware of the chemical composition of the material we are proficient in Marine Grade Aluminum Alloy Die-cast processing.

Chemical Resistant Powder Coating Ready

Omniluce provide customized chemical resistant coating over tri-valent chromating surface treatment total solutions to provide longevity for luminaires to operate for years ahead without maintenance.

Ingress Protection IP66 Sealed

Specically designed to withstand harsh conditions and wet locations with high pressure jet washable. Built tough to withstand constant exposure of dirt or dust in mining industry.

Impact Resistance IK10+ Vandalproof

Specially designed and carefully engineered to withstand the worst case scenarios in heavy duty lighting. IK10 test passed or higher standard achievable through our ready solutions.

Low Susceptibility To Vibration 3G Passed

Omniluce luminaires is designed to handle continuous exposure to vibrations. 3G vibration test passed to make sure the luminaires could withstand harsh conditions in crane lighting, conveyor lighting, etc.

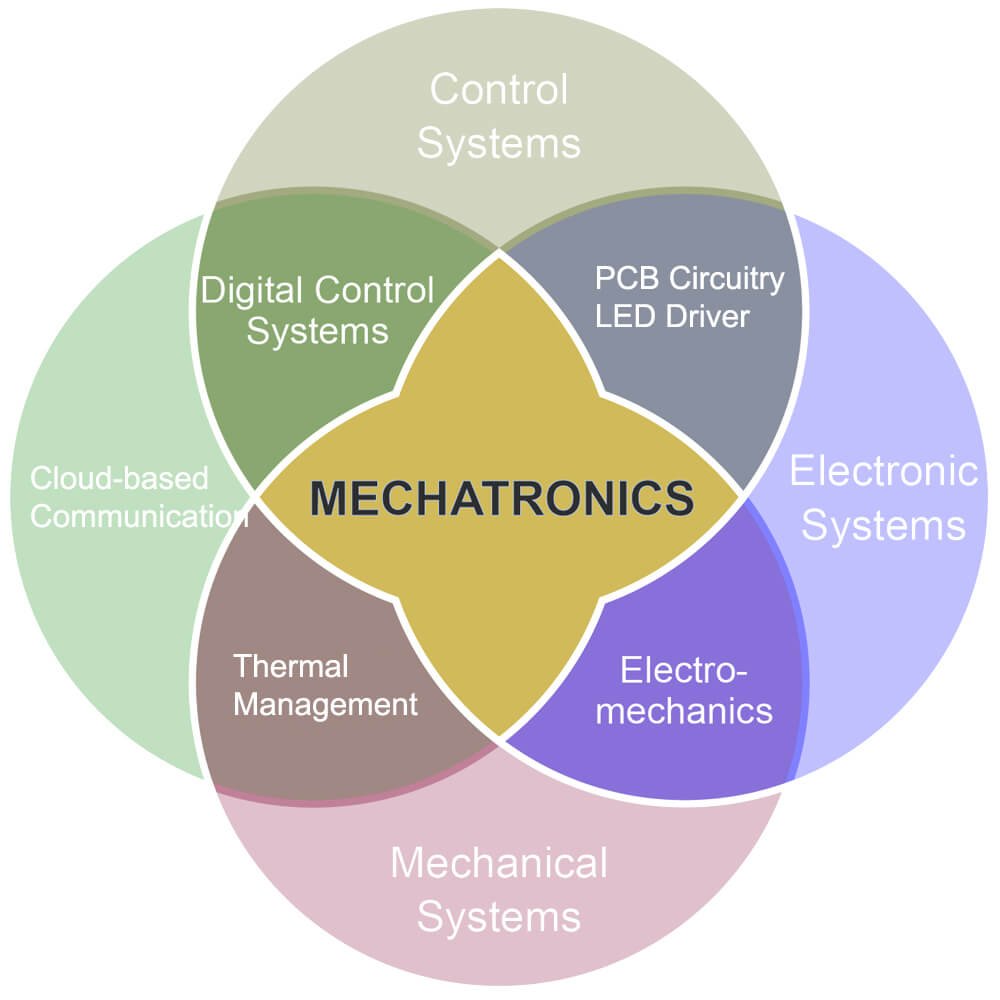

Mechatronic Integration Smart and Autonomy

High levels of integration fused by mechanical and electronic design, our products features orchestrated sophistication of details in terms of thermal management, electronic and engineering design.

Total Solutions To Make Sure The Luminaire Immune To Corrosion

Selective Housing Material:

We are fully aware of the composition of the raw material that we use to make heatsinks matters a lot in terms of corrosion resistance and structural strength. Thanks to our decades of experience we have options of various aluminum alloys which could be adopted to cater for different applications.

Marine Grade aluminum alloy has been a regular material used for our industrial floodlight heatsink specifically targetted to take heavy duty in harsh environments.

Surface Treatment & Coating Processing:

To address the corrosion issues, only material selected correctly is not enough, we have to implement a holistic powder coating system which involves chemical pretreatment over special coating processing.

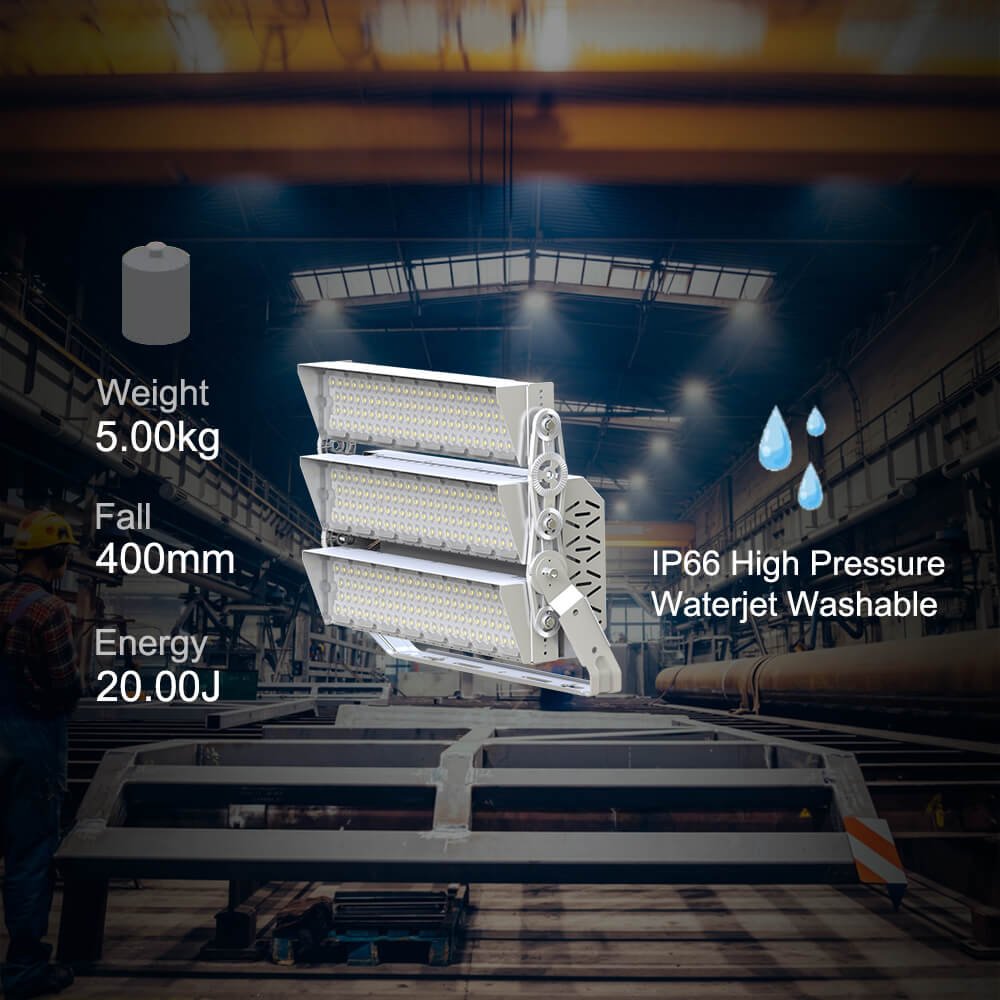

High Pressure Washable and Impact Resistant IP66 / IK10+

High Pressure Waterjet Washable:

In the worse case scenarios of typical industrial lighting the luminaire has to be specifically designed to be waterproof, and to take heavier duties. All Omniluce luminaires have been specially designed and carefully engineered to be IP66/IP67 which could be high pressure washable.

Impact Resistant:

IK10+ impact resistance is one of the the key performace for industrial lighting fixtures. The products of Omniluce are always designed to take heavy duty in the harshest conditions and survive the vandalism in the worse case scenerio.

3G Vibration Test Passed:

Most of Omniluce’s lighting fixtures for industrial uses could be vibration resistant when exposed to constant vibrating situations.

(3G) 3 times gravity or even (5G) 5 time gravity vibrations resistance could be handled

Mechatronic Integration Empowered By Electronic & Engineering Design

Electronic Design:

Unlike the traditional lighting company, our directors and engineers have extensive experience in electronics, which turns out a unrivaled advantage in solid state LED lighting applications especially when it comes to smart solutions.

Mechanical Deisgn:

Apart from the aforementioned robust design to handle structural strength and ingress protection function, we attach great importance to the thermal management of the core parts. Thermal coupling between the PCB and heatsink as well as the thermal partition between the driver and PCB areas have been well designed to deliver exceptional performance.

Engineering Control:

We designed speical devices to provide extra protection to the fixture to ensure longevity and keep the light operational without downtime to cut bills. We install thermal de-rating module to automatically reduce power in the event of overheat

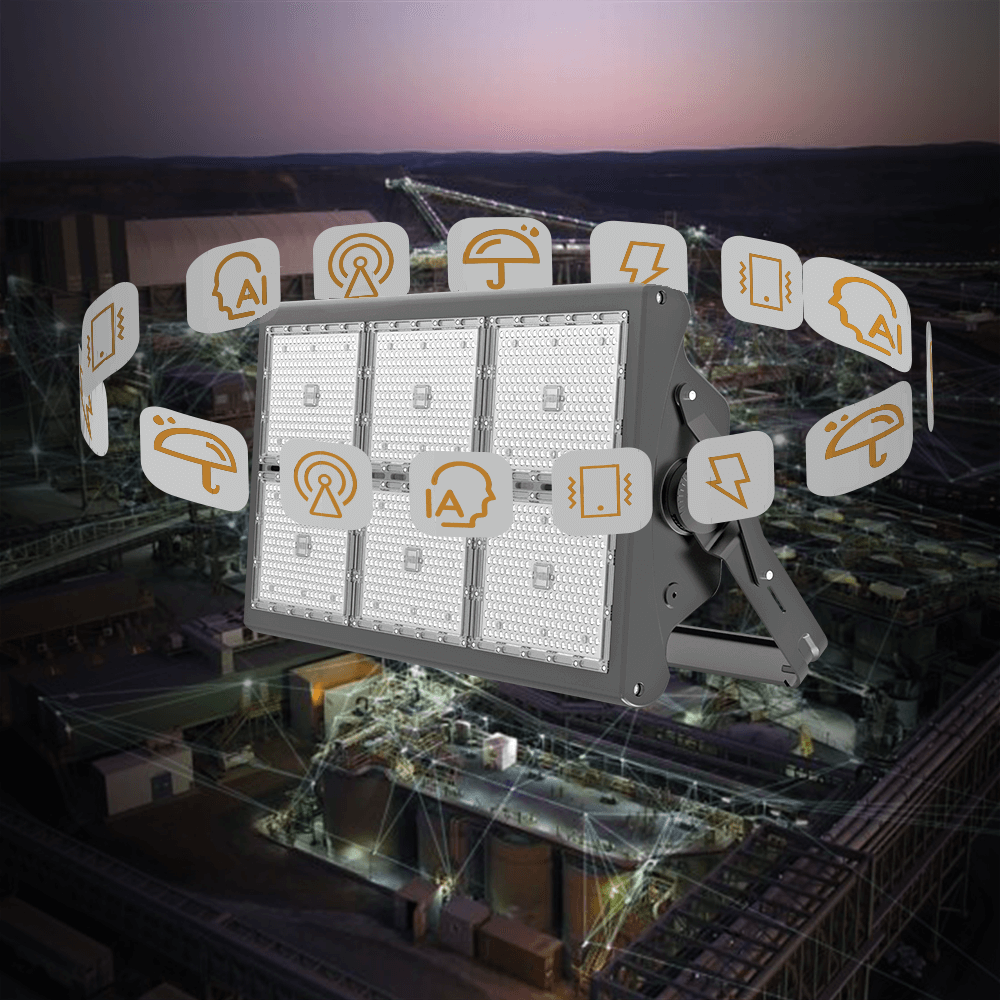

Smart Solutions Ready DALI / Zigbee / Cloud-based Control

To facilitate the end users’ convenience in daily operations and save power bills to reduce the total cost of the ownership, smart solutions have been widely used to integrated with light fixtures.

We have been pioneering the smart solutions with partners worldwide by using DALI, Zigbee, Casambi, Cloud-based wireless communications to empower the luminaires seamlessly connected and independently operated.